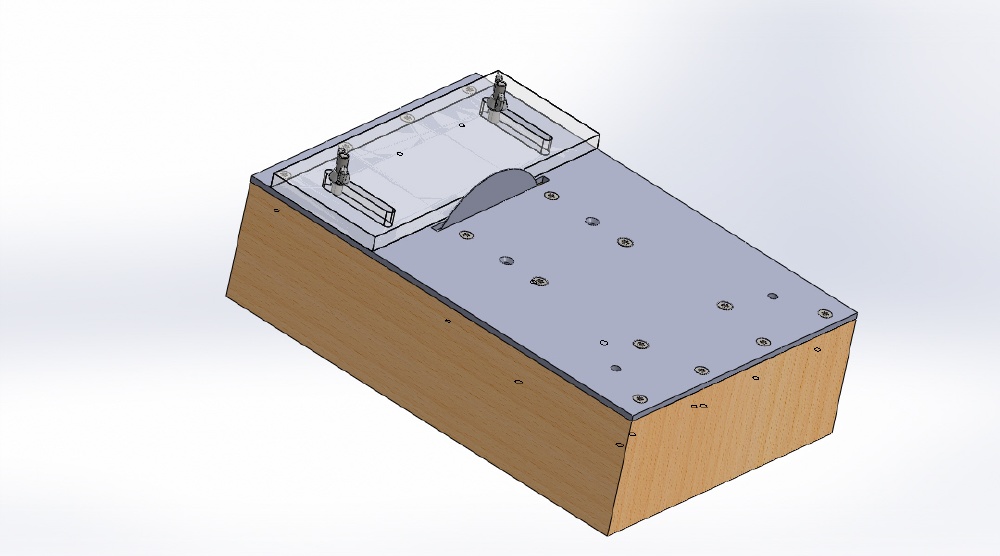

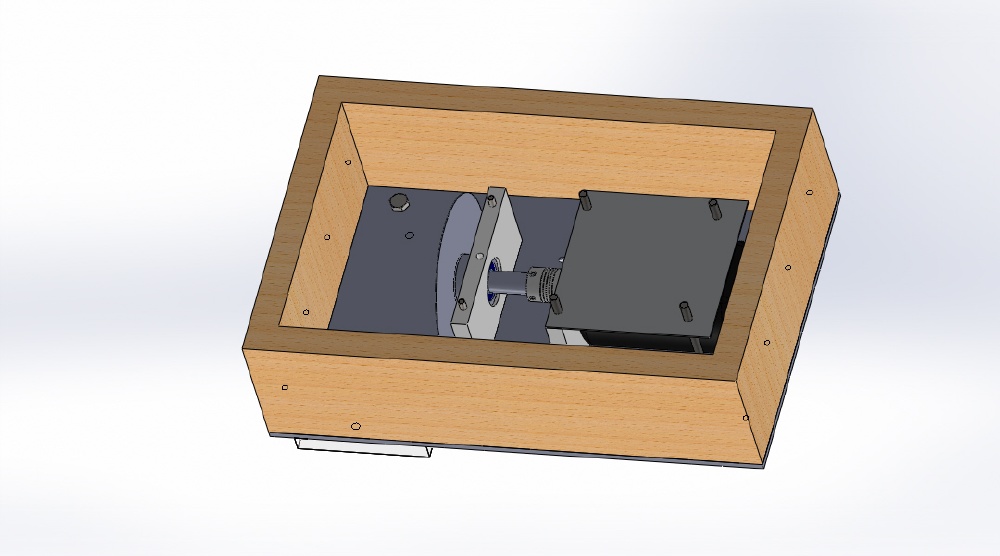

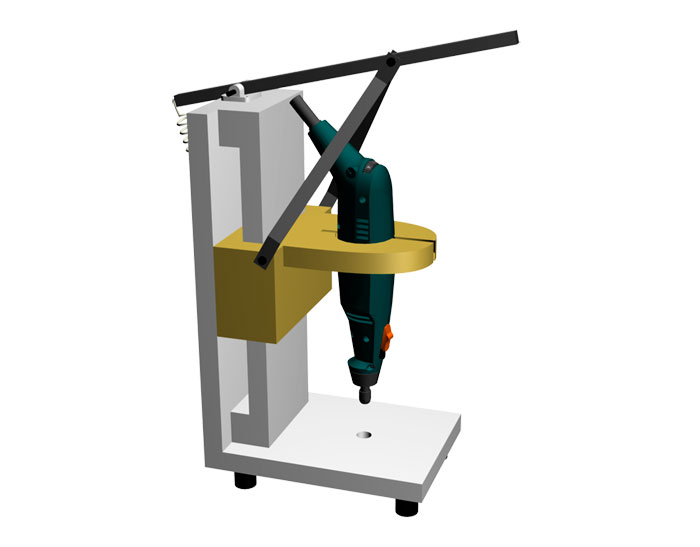

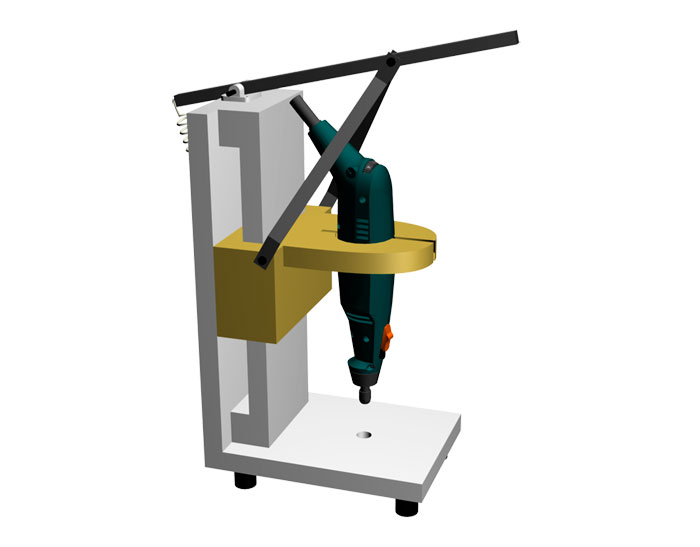

I was good for a vertical support to make holes with my dremel. The trade stands were either expensive, or very large, or both. So I started thinking a bit different I could do with what I had at home and this is what came out. First design in 3D Studio Max to see how things fit.

And after the rapid design to work. The list of materials that I have used is the following, although some things may not be ideal, I tried everything I could reuse:

And after the rapid design to work. The list of materials that I have used is the following, although some things may not be ideal, I tried everything I could reuse:

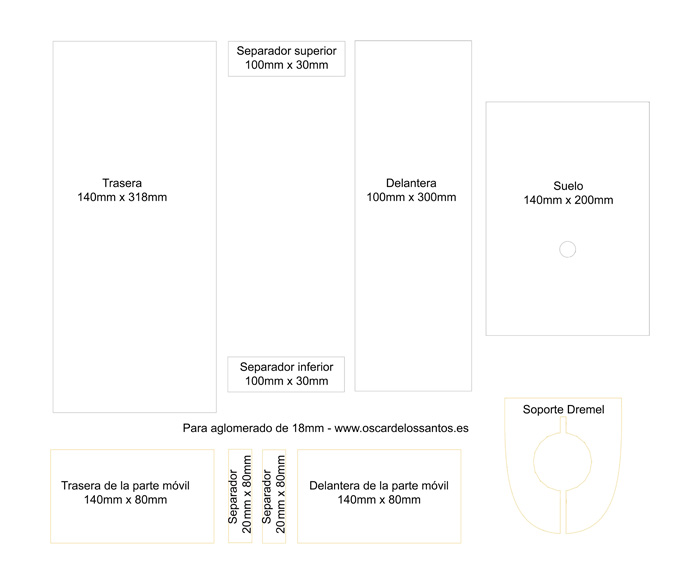

- A particle board (in my case 18mm thick)

- 4 rubber purchased from the Chinese

- 2 springs purchased at a hardware store

- Two «slats» aluminum which was home, purchased at Leroy Merlin

- A piece of aluminum square tube which was home, purchased at Leroy Merlin

- 2 screws M4

- 1 piece of which are used to hold the landing gear of the aircraft radio

- A couple of meters nicest butt to leave the edges of the timber cut

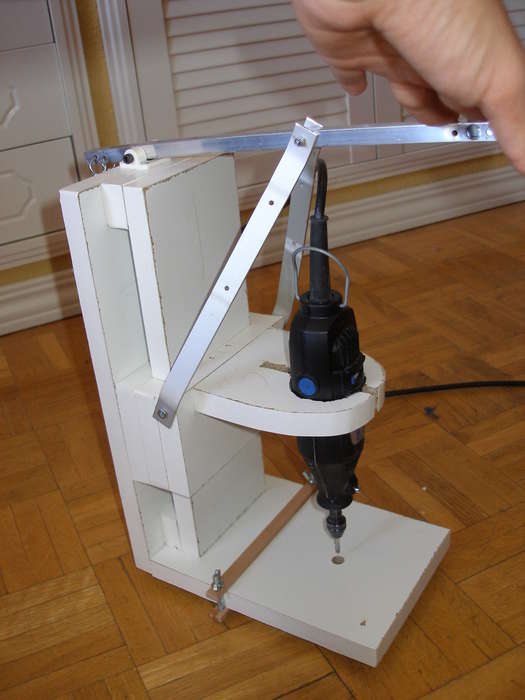

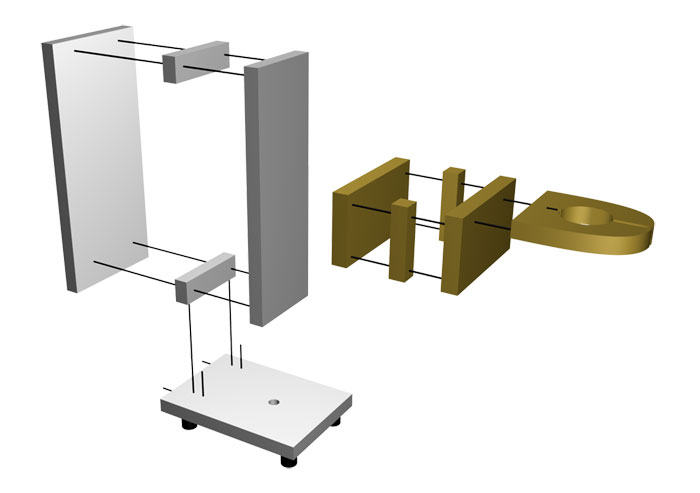

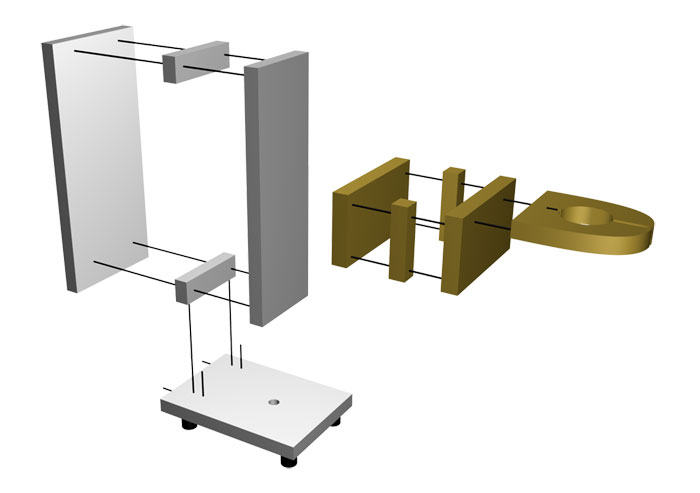

And here an outline of how they fitted the pieces. I’ve screwed with the coach and have been all made a stone. That if either carefully cutting straight timber, and carefully screw them right square. The yellow part is the phone will stuck in the white body finish turning before this. As the hollow inside is just the width of the wood we use (and separator used a piece of the wood itself), fits perfectly with the white part of the structure fixed. And then with aluminum slats and how each could properly is the upper arm and not much mystery.

At first I thought of holding the dremel by two points, but after attaching to the top came as pressure that is clearly subject and I think it is necessary. Surely done anyway putting a fastening point near the part of the drill will not move and nothing more accurate.

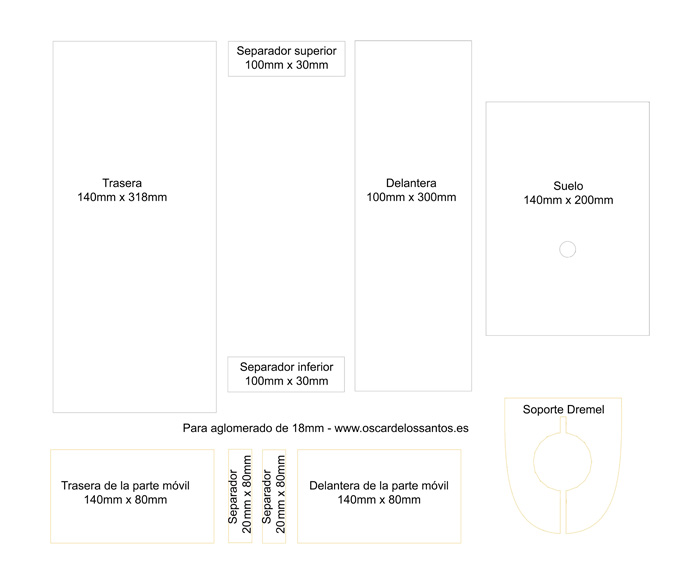

After build I added a small lane in order to support parts and I will even do some milling. This can be seen in the photos. The cost of all this …. I guess it will walk for 10 to 15 € (without the dremel course). All you have at home, for that which I less and save. in my case I only had to buy the docks. And above that is small in content and saved anywhere. And here a PDF of the sizes of each piece.

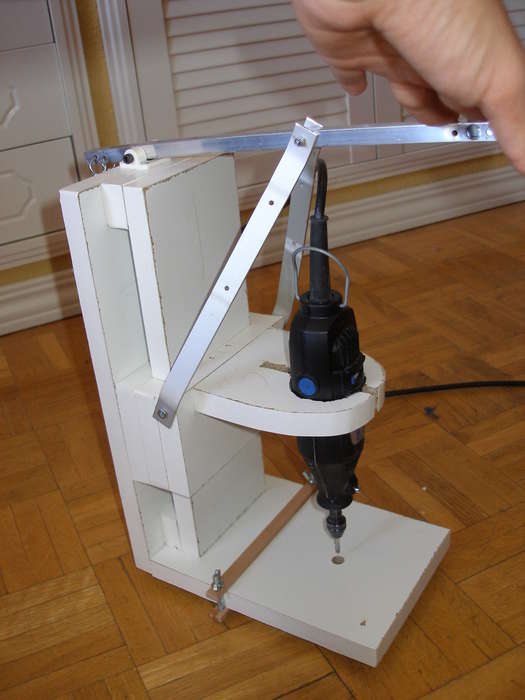

And here some actual photos of the invention. The finish is not very good, but it’s done in a hurry in a couple of hours.