One of the most important tools in any workshop, or DIY amateur, is a table saw. Since I don’t have a workshop and I am not used to make big things, my perfect tool would be this saw, but very small.

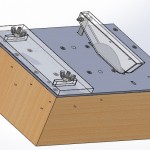

If we look for a small saw we’ll see that there are only two or three options in the shops, and are quite expensive. So, I opened the Solidworks in one hand and Google in the other y started to think what could I do with my limited tools.

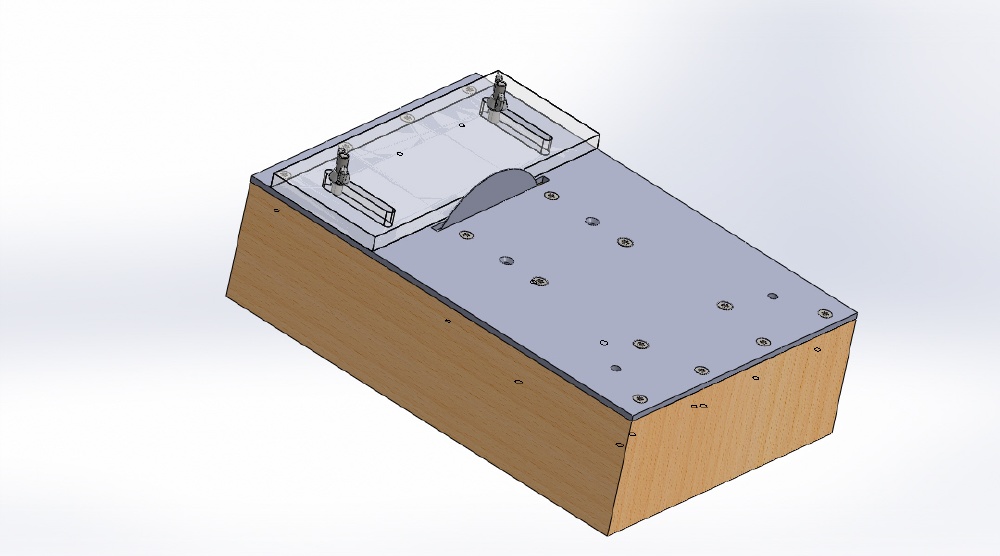

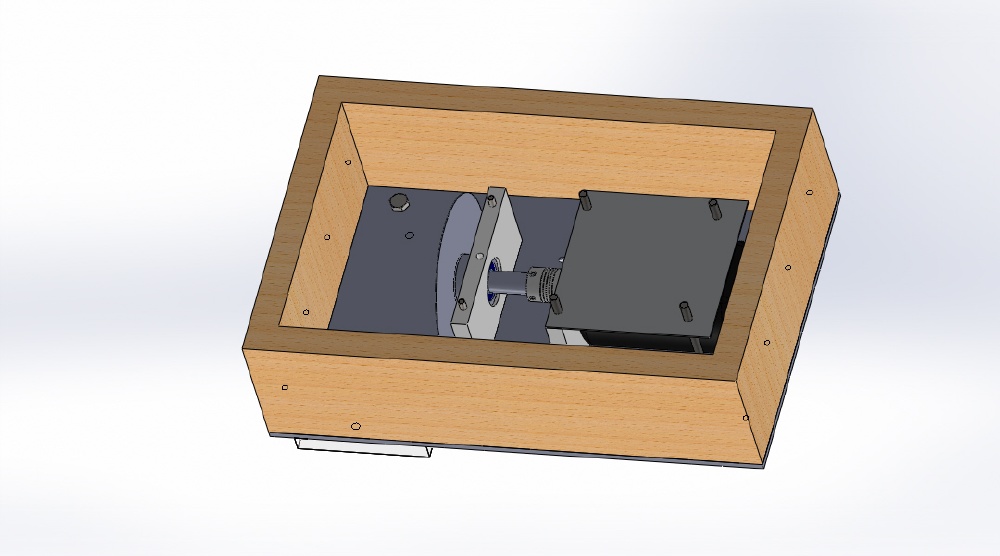

Finally, after a lot of hours and had studied a lot of other projects this was the result:

I bought the most of the parts in ebay and this is the list of materials:

- MDF Wood (if was cut and sent) – 12 €

- Aluminium sheet de 300 x 200 x 4 mm – 7 €

- Sew motor with pedal – 27,5 €

- Motor Flexible Coupling Coupler – 5,2 €

- HDPE sheet 10mm – 3.3 €

- Screws, nuts and washes – 7 €

- Aluminium sheet 100 x 100 x 3 to hold the motor – 2,3 €

- Bearing – 2,28 €

- Arbour – 13,9 €

- Circular saw 4″ – 7,29 €

SUM: 88 €

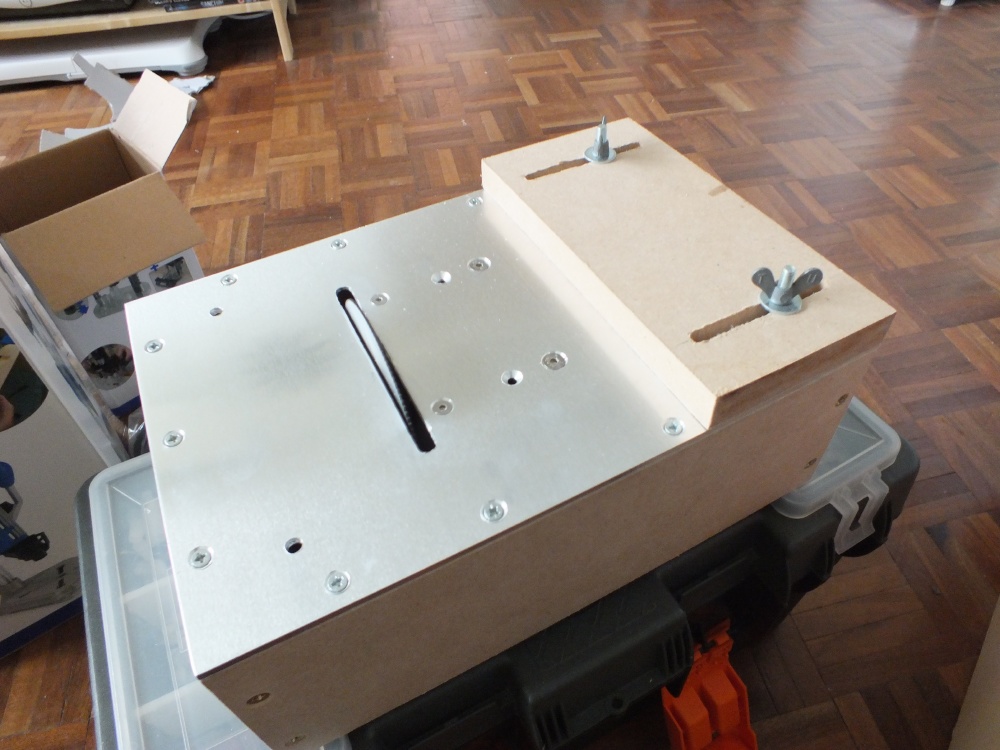

And this is the result:  Finally it’s no pretty cheap but it’s cheaper that the options in the shops, and I’ve enjoy a lot making it.

Finally it’s no pretty cheap but it’s cheaper that the options in the shops, and I’ve enjoy a lot making it.

Also, It’s can mount different types of saw (shaft diameter) and this it’s not usual. It has a cut of 20mm and this is a lot for this type of saws. In fact, I could increase the cut with a bigger disc.

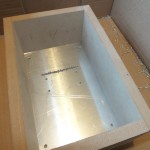

And here are the pictures…

Here is the video of the first tests. In the video I’m cutting HDPE (10mm) and MDF (18mm). The wood is cut worst but it’s because the saw has the teeth too small. Any way, the result is great.

I’m really happy with the result. If I would have had better tools I had made the bearing holder in aluminium, but…

* Update with a protector

After a bit more of Solidworks, a bit of plexiglax of 4mm and a couple of hours I have a protector.

* Second update

After some of work with the saw, I found out that the sew motor has not enought torque. Finally, Finally after forcing it burned. The solution has been to replace it with a 12V motor with gearbob. In particular this that operates at 12V and 1200 RPM. The result has been great, works much better, and cheaper. But you need a regulator or an adjustable power supply, to be able to regulate the speed of the motor.

My 10 inch saw bench is too big and clunky to perform small short cuts on thin and narrow stoc,k so was looking to buy or build something just like this. Thank you so much for taking the time to photograph and log all the steps in this fabulous builld. I will be using your plans and list to now put together my own mini saw table. Once again….many thanks.

Regards,

Alex Stick

Hello! I really loved your project! I intent to do something like this, because the comercial table saw are quite expensive! Thanks for sharing the those information.

Regards!

Hello very nice job! This was what i need to make my own table saw. Can i ask you what do you have to buy in order to put the blade in this motor «37mm 12V DC 1200RPM Replacement Torque Gear Box Motor» because i dont know what i have to buy. Best Regards

Hi Luis, are you Spanish?

Anyway, you need this:

http://www.rdgtools.co.uk/acatalog/Slitting_Saw_Arbours.html

and one of this (with the correct size):

http://www.ebay.co.uk/itm/130883392169?ssPageName=STRK:MESINDXX:IT&_trksid=p3984.m1436.l2649

Hello Oscar, so far i have the same motor as you:

http://www.ebay.co.uk/itm/190644764557?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649

this motor mount for it: http://www.ebay.co.uk/itm/321130465361.

Now a need to know what Arbour do you have?? By the picture it looks this one: SLITTING SAW ARBOUR 2 MORSE TAPER Ref: 699 from the link that you send me. Can you please tell me the diameter of that so i could buy a 6mm Motor Shaft Coupler Coupling for it. Thanks.

BTW i´m from Portugal 😉

You need this one:

SLITTING SAW ARBOUR STRAIGHT SHANK 1/2″ DIA

Ref: 701

because is the only one with a straight shank. The shank diameter is 1/2 inches

Hi!

Thanks for your posting. I also cosidered table saw for long time.

And finally made my own. I inspired from your project. 🙂

Please see my project in site below (It’s not english just see the pics and video.)

Thanks again.

http://cafe.daum.net/iloveqrp/Kkv6/363

Hi Chan,

I’m sorry but I can not see your website. do I need to login?

Valuable info. Fortunate me I discovered your web site accidentally, and I’m stunned why this twist of fate didn’t happened in advance!

I bookmarked it.

Hola Oscar, soy de México, y quisiera saber que motor y materiales en general utilizaste, la pienso usar para cortar marcos de fotografías y así, saludos de antemano

Hola Oscar, te escribo de México, pienso construir una sierra como la tuya, pero no sé qué materiales me funcionen, sobre todo el motor, pienso utilizarla para cortar perfiles de los que usan para marcas de fotografías, saludos y espero me puedas apoyar, abrazo desde México